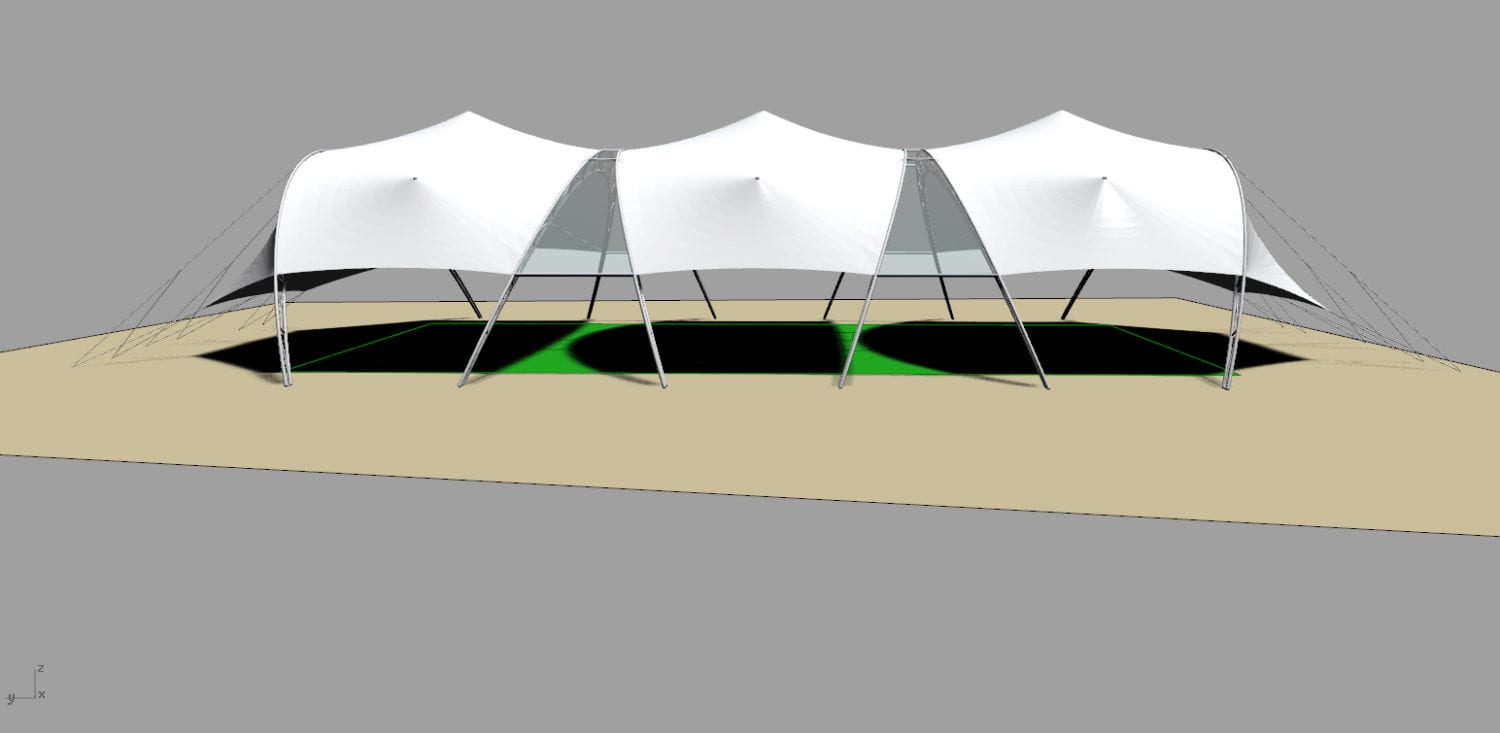

Tensile Fabric Cover Type & Shape

For any Tensile Fabric Structure, the cover type and shape will determined firstly by the environment and the end use. To that end, the Toro Design Engineers will undertake a comprehensive survey of your environment and take time to assess all your requirements. Consequently there will ultimately sometimes be a compromise to be made during the planning and design stages. Therefore the experts at Toro will be on hand to guide and advise all options, timelines and detailed costings to help you find the right solution for your project.

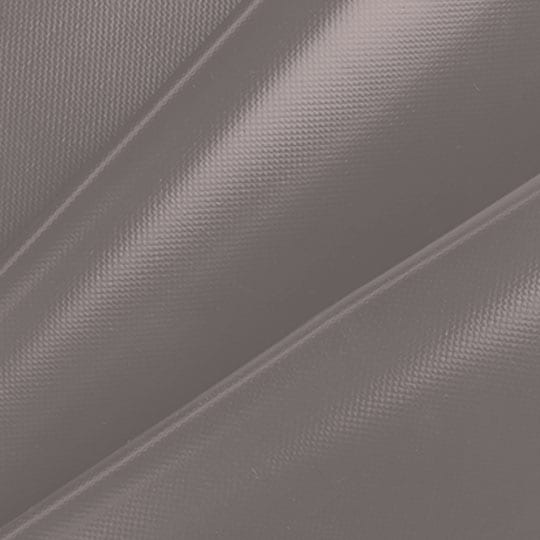

Robust, High Quality PVC Tensile Fabric Membranes.

Each and every Toro Tensile Fabric Membrane cover is designed for your specific operating environment. Similarly, for multiple environments if your structure is relocatable.

The incredibly strong composite tensile fabric membranes that cover the buildings are UV stabilised, tried and tested in the Middle East and Africa. They transmit enough light to negate the need for artificial lighting during daylight operation and remain impervious to wind, rain, snow and chemical attack.

Like our steel trusses: Toro PVC fire-resistant, tensile fabric covers are made from the highest quality European fabric. They will last for a generation. They are backed by a 5-year warranty. Toro Shelter tensile fabric covers contribute to the lasting durability of our fabric buildings just as much as our steel trusses. For structures less than 30m wide, we use a one-piece cover to fit the frame. This ensures a secure, leak-free tensile fabric cover. For larger structures, we use multiple tensile fabric covers and weld them together on-site.

Toro Builds to Eurocode Standards

We Only Use The Highest Quality Materials and Components

Customised Design Specification

Multiple industries require tensioned fabric buildings for a broad spectrum of use, and there’s wide range of options available on the market today, but many of them are strictly modular in format. Therefore clients have to adapt their working environment to fit the space rather than the other way around.

High Quality UK Fabrication

At Toro, we pride ourselves on our work ethic, our fabric strucures and our ability to make great things happen. As a consequence we demand the highest level of engineering, manufacturing, quality control and assurance from our UK manufacturing plant. To that end, the business has invested heavily in R&D, innovation and lean manufacturing techniques in order that we can surpass our clients expectations.

Toro Steel Frames

Toro fabric buildings use the highest quality European structural steel tubing. Our structures are fabricated in Europe. We will never use cheap, low quality, steel from an unknown source.

Our steel frames are manufacvtured by some of the most professional and skilled operators in the world.

In order to provide custom-engineered structures, we construct each steel truss individually to meet exacting design specifications. Hence our steel tubes are cut and bent, they are welded together to create a webbed effect, exactly as the design engineer intended. As a consequence our structures have an unmatched strength that Toro Shelters are renown for within our industry.

All of our fabric buildings use the latest technologies, materials and innovations to provide the best products on the market. To make sure our quality remains consistent, Toro fabric buildings use the highest quality European structural steel tubing, are fabricated in Europe, and we will never use cheap, low quality, steel from an unknown source. With this in mind, if you find your design specification is not available elsewhere, Toro can make it happen.

Each section of the structure to hot dipped galvanise the frame, strengthening and protecting it from harsh environmental conditions. This is a highly skilled task that requires a great deal of experience to get the right degree of accuracy throughout the structure. As a result Toro Shelters will always accurately slot together using industry leading fixings once on site, and last a lifetime.

Finally, each weld, cut, fixing and section is checked and re-checked and then fully certified before it leaves the manufacturing plant.

Choosing the correct Cover Types & Shape for your environment.

For any Tensile Fabric Structure, the cover type and shape will determined firstly by the environment and the end use. To that end, the Toro Design Engineers will undertake a comprehensive survey of your environment and take time to assess all your requirements.

At Toro Shelters, we pride ourselves on offering only the best advice and support for our clients. To that end, we will not compromise on our understanding of your project requirements. Consequently we will treat your project as if it were our own and help you understand the features and benefits of each design option. As a result we believe that we will deliver a product that surpasses your expectations, delivered on time and on budget.

Common Cover Colours

The below colours can all be supplied immediately. Specific colour matching is available but may increase lead times and costs.

Toro is an award-winning company. We consistently deliver the highest levels of innovation, quality and service in the industry.

Toro Foundation Types

There are many foundation options available for use with tensioned fabric buildings, and cost is always a factor when making a decision.

Whatever your structure needs are, the first consideration in determining the right kind of foundation is whether your structure is temporary, relocatable or permanent.

Generally speaking, temporary foundations will be less expensive but will limit the size of buildings they will support, and will also not last as long as permanent foundations.

Toro Client Testimonials

We purchased a mining equipment maintenance shelter from Toro Shelters in 2014. Located in the sub Saharan desert area experiencing sand storms and high temperatures and heavy rains, the shelter, its modular offices and workshops, 5 years later are still in perfect condition.

SOMIVA, SENEGAL

A Good design, a good quality product and an installation team who over-came the many challenges.